Sibolla Building : Complete Building Material Solutions for Global Projects

Browsing on a Computer Will Give You a Different Experience.

Large and Professional Team

Cooperating Factory

Projects Completed Each Year

Integrated Project Material Solutions

One Team. One System. One Coordinated Supply.

Sibolla Building delivers fully coordinated building material packages tailored to each project. From floor plans to final shipment, we manage design coordination, engineering review, material matching, procurement, and custom production — ensuring every element works together seamlessly.

Our scope covers cabinetry, doors and windows, bathroom systems, stone and tile, lighting, furniture, and soft furnishings. With centralized project management, digital production tracking, and global logistics, we help developers and contractors reduce risk, control budgets, and keep construction on schedule.

Sibolla Building Material Products

Built by System, Delivered by Expertise

Manufacturing, customization, and project-level coordination — all under one integrated supply system.

Sibolla Building operates within a structured manufacturing and supply network that supports full-scope project material delivery. From cabinetry and millwork to doors, windows, stone, lighting, and furniture, every component is engineered, produced, and quality-controlled to align with project specifications.

With digital production tracking, pre-shipment coordination, and global logistics support, we ensure materials arrive complete, consistent, and construction-ready — helping developers and contractors maintain timelines, control budgets, and reduce on-site complications.

Saudi Arabia Project Case — Inspection, Mock-Up & Export Delivery

A full bathroom package prepared, verified, and shipped under project-level quality control.

This Saudi Arabia project demonstrates Sibolla Building’s structured project delivery process. From factory inspection and trial assembly to room-by-room labeling and export-grade packing, every material component was verified against drawings and protected for long-distance transportation.

Our QC system covered dimensional checks, functional testing, finish inspection, and packing validation. With full traceability records, optimized container planning, and on-site installation readiness, the shipment arrived organized, compliant, and construction-ready — reducing delays and minimizing project risk.

Why Choose Sibolla Building

Structured. Accountable. Project-Focused.

Sibolla Building combines engineering coordination, manufacturing integration, and global supply experience to support full-scope project material delivery. With nearly two decades of industry expertise, we work alongside developers, contractors, and design teams to ensure materials are specified correctly, produced consistently, and delivered in alignment with project schedules.

Our role goes beyond sourcing. We act as a centralized coordination partner — managing customization, cross-category integration, quality control, and export logistics under one system. This reduces procurement complexity, minimizes on-site risk, and provides a single point of accountability throughout the project lifecycle.

A multidisciplinary team supporting engineering coordination, production management, quality control, and global project delivery.

What We Deliver for Your Project

A coordinated system covering design alignment, material integration, cost control, and global delivery.

Design & Specification Coordination

Support in translating design intent into buildable material specifications, helping align finishes, dimensions, and performance requirements across the project.

Global Project Delivery Management

Structured export packing, container optimization, documentation control, and logistics coordination ensure materials arrive complete, protected, and installation-ready.

Project-Specific Material Integration

Material packages engineered according to project layouts, specifications, and functional requirements — ensuring cross-category compatibility and design consistency.

Cost-Optimized Sourcing System

Integrated supply planning and factory coordination reduce procurement complexity and control total project material costs without compromising quality.

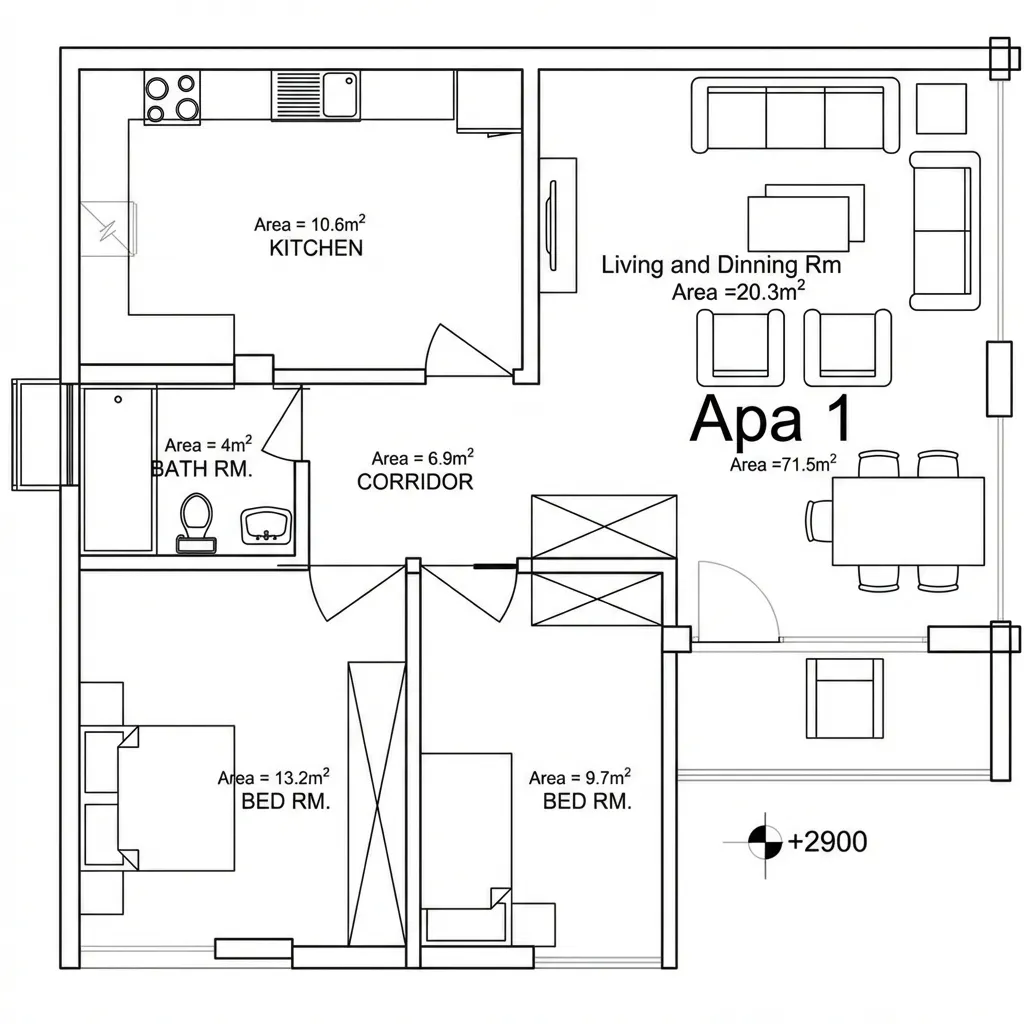

81 m² Full-House Customization — Real Client Home Tour

A real 3-bedroom, 1-bath makeover that stayed calm and organized from the first moodboard to move-in. One palette was carried through the kitchen, living room, bedrooms, and bath. Weekly check-ins and clear drawings kept decisions simple, while room-labeled deliveries made installation predictable. No drama on site—just steady progress and a homeowner who enjoyed the process as much as the results.

Watch their YouTube tour and see what a smooth, happy collaboration looks like.

The Infrastructure Behind Sibolla Building

Reliable scale, precision, and coordination for international builds.

Sibolla Building is backed by a structured manufacturing and supply network that includes 200+ advanced automated factories and a team of 1,000+ skilled professionals across engineering, production, quality control, and logistics. This infrastructure enables consistent multi-category production, precise customization, and scalable output to support projects of varying sizes and complexities.

With coordinated factory systems, digital production processes, and export-ready supply management, we ensure stable lead times, controlled quality, and synchronized delivery — providing reliable material support for large-scale residential, hospitality, and commercial developments worldwide.